Boiler Operational Maintenance

Like your car, a bit of regular maintenance can make all the difference to your boiler or air conditioning – it keeps your costs down in the long-term. You might need to get someone in to help you, but it will keep your equipment working at its best, and may save on future maintenance and repair bills

Why not?

- Check that your boiler stops firing when the thermostat or timer shuts off the circulating pump. Boilers that continue to fire when the pump is off are wasting you money

- Regularly check and maintain any air conditioning units you have and ensure air filters are free from dust. Even a small reduction in airflow will increase running costs, so keep them clean and replace them as necessary.

- Ensure annual boiler services include a combustion efficiency check and adjust the burner air/fuel ratio to ensure maximum efficiency (in line with manufacturer’s instructions).

Why not ask your engineer to modify the control system so that the timer/thermostat switch shuts off both the circulating pump and the boiler itself.

Pipework

Uninsulated pipework can be a significant source of heat loss and wasted energy – it acts as an uncontrolled heating source in areas you might not want it, and takes useful heat away from areas that need it. Simply insulating pipework can reduce energy losses by 70% and ensure the levels of comfort you want.

Extraction System

While adequate air extraction is often necessary, taking excessive air away is expensive and can create uncomfortable working conditions. The simple solution is to control the operation of extractors through timers or interlocked controls to prevent unnecessary extraction.

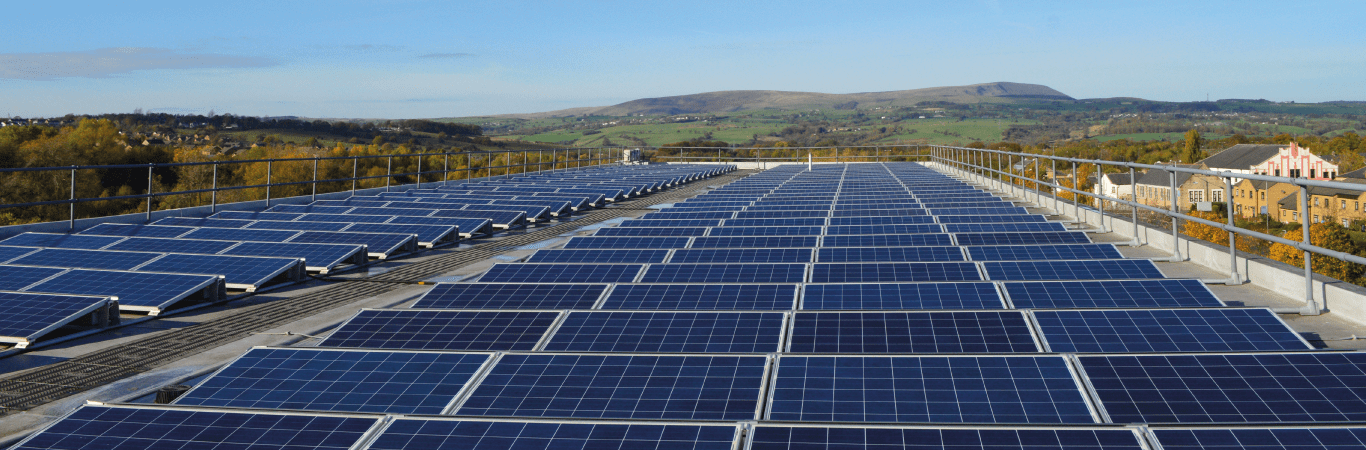

Energy Technology

Energy Technology

Powering your present. Preserving your future.

Call us on 01282 421 489

strategy be a priority?