The twin challenges currently facing the UK manufacturing industry

It’s been an exceptionally turbulent year not just for the UK, but the entire global population. The one-two punch of the onset of Covid-19 and the subsequent national lockdown meant that almost every sector took a substantial hit, not to mention the damage to the British economy as a whole.

Some industries (such as retail) took the brunt of the lockdown even harder than others, whereas others were able to cope a little better. The manufacturing sector holds the peculiar distinction of spanning across both camps, with some businesses having been forced to close their doors to the public, whereas others were able to survive with only a relatively small impact on their business.

Now as we move into the later months of the year, the sector as a whole faces a two-pronged challenge to not only survive, but thrive in the new normal. And what’s more, many are turning to commercial solar to help them do so. But before we get into that, let’s explore a bit about the challenges themselves.

Challenge #1 – the economic impact of Covid-19

This is the most obvious – and for many, the most pressing – issue that UK manufacturing businesses are currently facing. As we touched on above, there’s an interesting duality to the impact of Covid-19 on the sector. Demand for commodities such as vehicles and wholesale products fell dramatically, while things like household products and home gym equipment experienced huge spikes in sales. Covid-19 was just as much of a boon to some manufacturing businesses as it was a detriment to others – it really depended on what you manufactured.

Many manufacturers were even able to adapt their operations in direct response to the onset of the virus, shifting their efforts to produce PPE, protective plastic screens, and similar physical defences or measures against Covid-19. But obviously, not all manufacturers were capable of this sort of shift, and many of them faced the daily realities of increased freight and supplier costs, and extended delays on the arrival of key materials or components.

However, according to a recent survey by edie, the manufacturing industry as a whole appears to have coped well in terms of its ongoing sustainability plans, proving that it remains an ever-higher priority in the eyes of many in the sector. Of all the respondents to edie’s survey, less than one in five delayed or postponed any impending sustainability announcements.

Challenge #2 – how to champion a green recovery

Edie’s survey actually yielded quite a number of interesting conclusions. 85% respondents in the manufacturing sector either agreed or ‘strongly agreed’ that the green recovery presented an invaluable opportunity to fast-track climate action. Here at Low Carbon Energy, we actually wrote a pretty extensive post on that topic ourselves at the time.

Now, reducing emissions down to basically zero is always going to be a difficult task for any industry, but for many in the industrial sector it’s nigh-on impossible with the current technology we have available. Therefore, most businesses have set themselves the challenge of reaching Net Zero instead, which is the most realistic target we have right now.

However, there’s still a significant challenge involved in how to actually get there. Many manufacturing processes are inherently energy intensive, which is one of the biggest difficulties faced by the industry. Cement, steel and plastics manufacturers in particularly are exceptionally difficult to decarbonise, partially because many of these processes release CO2 as an intrinsic part of the manufacturing procedure.

Those are just a few examples, though – almost every individual manufacturing business will have its own distinctive set of challenges to overcome.

So how can manufacturing businesses deal with these problems?

But while it might be difficult to reach Net Zero, it’s far from impossible, and there are plenty of other ways that organisations can cut down on their emissions. The impact of Covid-19 means that implementing cost reductions and operational efficiency has never been more important, and manufacturing businesses can tackle both problems head-on by building energy sustainability directly into their economic recovery plans, and proactively looking for ways to become more efficient and agile.

For example, if any vehicles in a business fleet are reaching the end of their operational lifespan, or they have been phased out due to reduced demand since the lockdown period, businesses can switch them out for electric variants, saving themselves on long-term fuel costs.

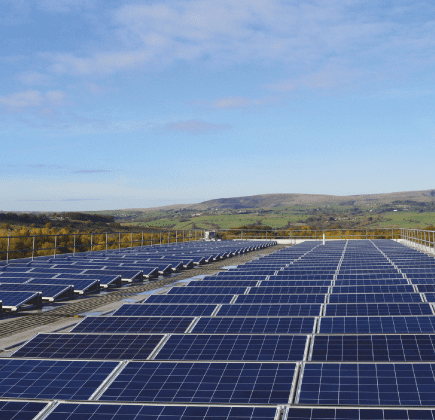

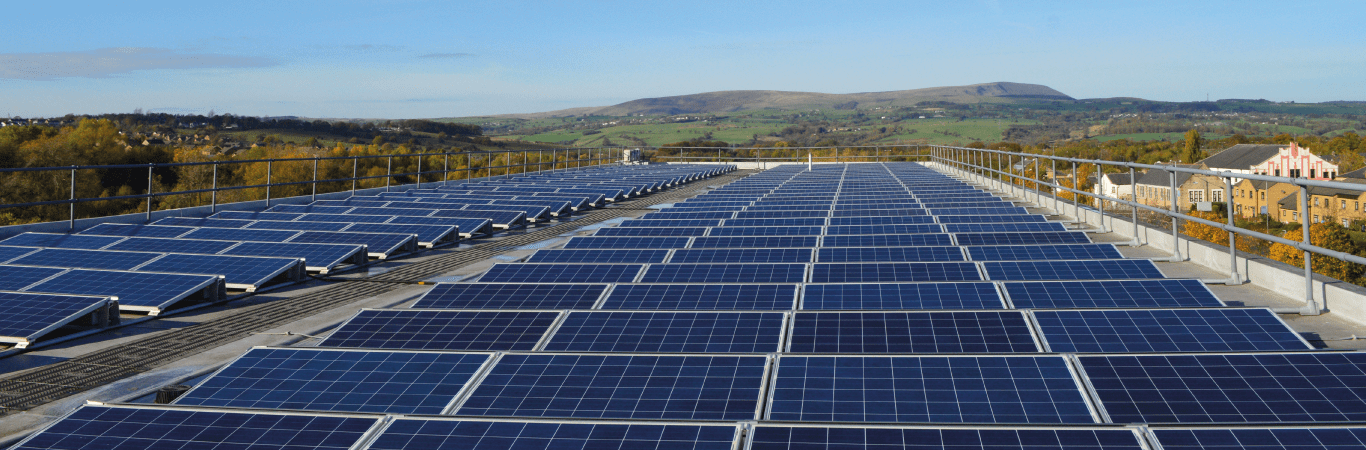

A smarter management of energy consumption is also an effective way to address the need for greater climate action and cost-saving measures, and this is where commercial solar comes in. As of 2020, the UK is the 3rd largest solar energy producer in Europe, and manufacturing businesses all over the country are starting to reduce their reliance on the national grid, instead using solar to generate a secure, low-cost supply of energy on their own premises.

Apart from the direct cost savings, there are a substantial range of secondary benefits associated with this, too. Recent research has proven that climate action is a major draw for customers and investors, and businesses with solar panels stand to benefit from a tangible boost in their CSR.

If you’re considering solar panels for your own manufacturing business, you can find out more about the advantages of solar right here on our site. Alternatively, you can take a quick look through our case studies to see how we’ve already helped businesses just like yours to reap the rewards. To find out how we can help you, feel free to give us a call today on 01282 421 489!

Energy Technology

Energy Technology

Powering your present. Preserving your future.

Call us on 01282 421 489

strategy be a priority?